Device Fabrication Facilities

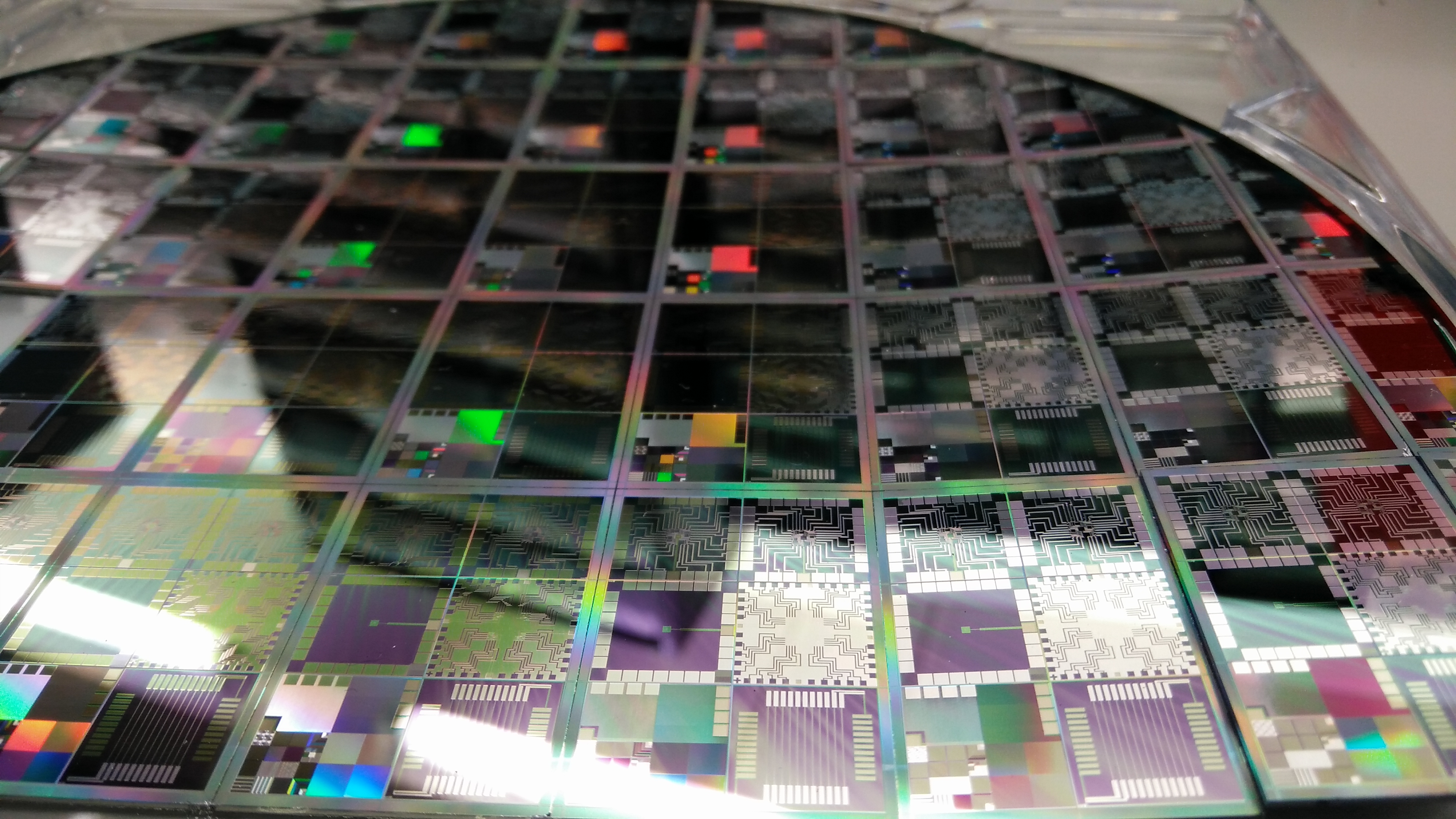

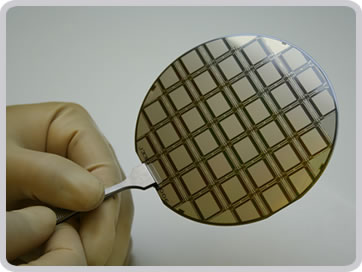

CMMPE mostly use the CAPE cleanrooms to fabricate complex bespoke electrical and optical devices. Custom-made liquid crystal and optical telecommunication devices are constructed with unique electrode configurations and alignment layers. These devices are produced using advanced chemical processing and photolithographic techniques.

Cleanrooms

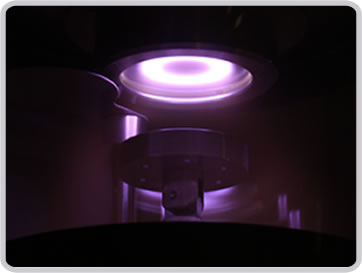

CMMPE shares in the CAPE building’s extensive cleanroom facilities. The cleanrooms encompass the entire top floor of the building and are comprised of separate class 10k, 1k and 100 areas. From here, access to a wide range of advanced liquid crystal, semiconductor and nanotechnology processing equipment is available.

Rapid Prototyping & Cell Fabrication Facility

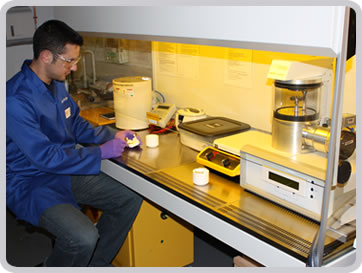

CMMPE also has its own dedicated preparation laboratory, which consists of a scaled-down version of many of the facilities provided in the cleanroom. This space is suitable for the small-scale production and rapid proto-typing of liquid crystal cells and devices.

Facilities include:

- Recirculating laminar flow (class 10) workstation

- Spin-coater for polymer and alignment layer deposition

- Sputter-coater for metal deposition (including Al, Cr, ITO)

- Photolithographic patterning equipment (for optical waveguide structures and electrode patterning).

- Microbalance for liquid crystal, polymer and dye mixtures