|

|

|

|

CGC Class 1000 Cleanroom Equipment

|

|

|

|

Below, you can find the list of equipment available in Class 1000 Cleanroom. A few are already available for use, others are being installed and will become available later.

Please use the booking system to use the equipment.

|

|

|

|

Plasma-Enhanced Chemical Vapour Deposition system (PE-CVD)

Model: Vision 310, Advanced Vacuum AB

Used for plasma-enhanced chemical vapour deposition system is used for depositing amorphous Si, SiO2 and Si3N4.

Gases connected: SiH4, NH3, N2O, N2

Users in charge:

|

|

|

|

|

Reactive Ion Etcher (RIE)

Model: Vision 320, Advanced Vacuum AB

Used for reactive-ion etching of Si, SiO2 and Si3N4.

Gases connected: SF6, CHF3, C4F8, CF4, O2, Ar, N2.Compatible only with the following substrate/mask materials:

Si, Al, PR, SiO2, Si3N4 (exposed noble metal parts/masks are not allowed).

Users in charge:

|

|

|

|

|

Inductively-Coupled Reactive Ion Etcher (ICP-RIE) "APEX"

Model: APEX SLR, Advanced Vacuum AB

A load-locked system for inductively-coupled reactive-ion etching of Si, SiO2 and Si3N4 with an enhanced rate and anisotropicity.

Gases connected: SF6, CHF3, C4F8, CF4, O2, Ar, N2

Compatible only with the following substrate/mask materials: Si, Al, PR, SiO2, Si3N4 (exposed noble metal parts/masks are not allowed).

Users in charge:

|

|

|

|

|

Inductively-Coupled Reactive Ion Etcher (ICP-RIE) "Oxford"

Model: PlasmaLab 100, Oxford Instruments

A load-locked system for inductively-coupled reactive-ion etching of Si, SiO2 and Si3N4 with an enhanced rate and anisotropicity.

Gases connected: SF6, CHF3, C4F8, CF4, O2, Ar, N2

Compatible only with the following substrate/mask materials:

Si, Al, PR, SiO2, Si3N4 (exposed noble metal parts/masks are not allowed).

Users in charge:

|

|

|

|

|

Reactive Ion Etcher "NanoEtch"

Model: NanoEtch, Moorfield Nanotechnology Ltd

The tool implements a unique soft-etching technology and provides the fine etching control crucial for graphene and 2D materials research in a convenient, benchtop package.

Gases connected: CF4, O2, Ar, N2.

Users in charge:

|

|

|

|

|

Plasma Cleaner "Femto"

Model: Femto, Diener Electronics GmbH.

This is a low-pressure plasma system used for plasma cleaning of substrates and activating surfaces. Gases connected: O2, N2.

Users in charge:

|

|

|

|

|

Electron-Beam Evaporator/Sputterer

Model: PVD 200 Pro, Kurt J. Lesker

This PVD tool is used for e-beam evaporation and sputter deposition of metals dielectrics.

Materials: Au, Ag, Cu, Cr, Ti, Al, Ni, Sn, Mo, ITO, SiO2, Al2O3.

Users in charge:

|

|

|

|

|

Thermal Evaporator

Model: MiniLab 60, Moorfield Nanotechnology Ltd

Features: Manual and Automatic process modes, HMI, used for a thermal evaporation of selected metals.

Materials: Au, Ag, Cr, Al.

Users in charge:

|

|

|

|

|

Atomic Layer Deposition (ALD)

Model: TFS200, Beneq

Used for Atomic Layer Deposition of Al2O3 and TiO2. Materials: liquid TMA and TiCl4 precursors.

Users in charge:

|

|

|

|

|

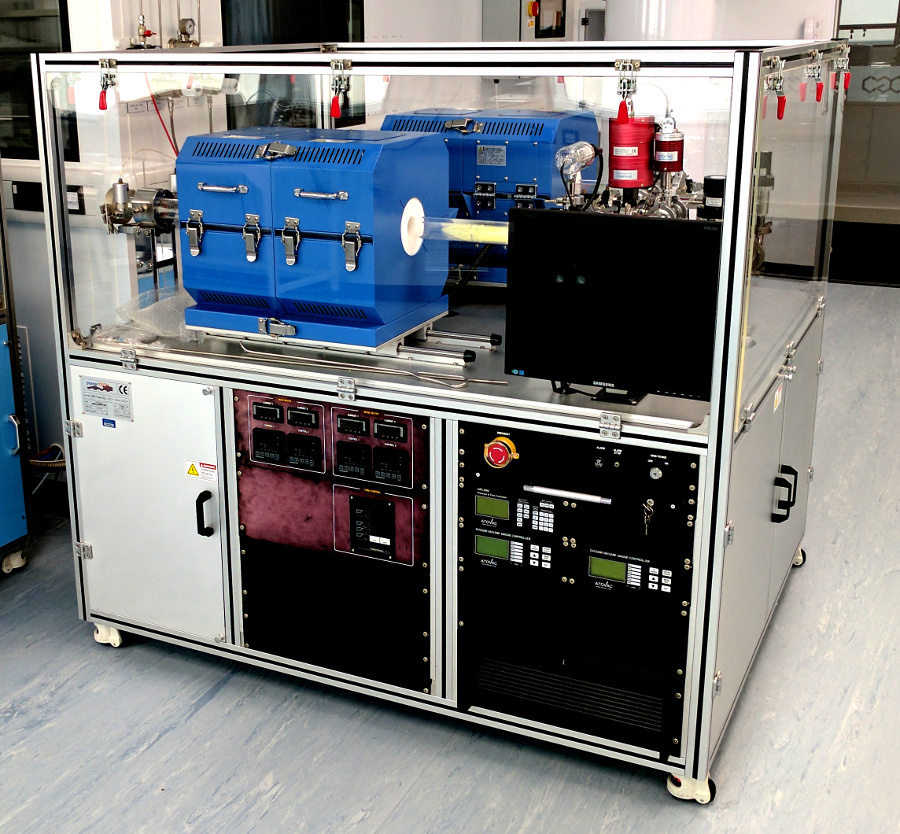

Ar-filled Glovebox

Model: M-Braun

Inert-atmosphere (Ar) glovebox with a robotized 3D graphene transfer system and a thermal evaporator. The thermal evaporator can be accessed from the inside as well as outside of the glovebox. There is a spinner and a hotplate inside.

Users in charge:

|

|

|

|

|

Transition-Metal Dichalcogenides Chemical Vapour Deposition system (TM-CVD)

Model: Planartech

A dual-furnace Chemical Vapour Deposition system for growth of 2D materials.

Users in charge:

|

|

|

|

|

Plasma-Enhanced Graphene Chemical Deposition system (PE-G-CVD)

Model: Planartech

Plasma-Enhanced Chemical Vapour Deposition system for growth of high-quality graphene.

Users in charge:

|

|

|

|

|

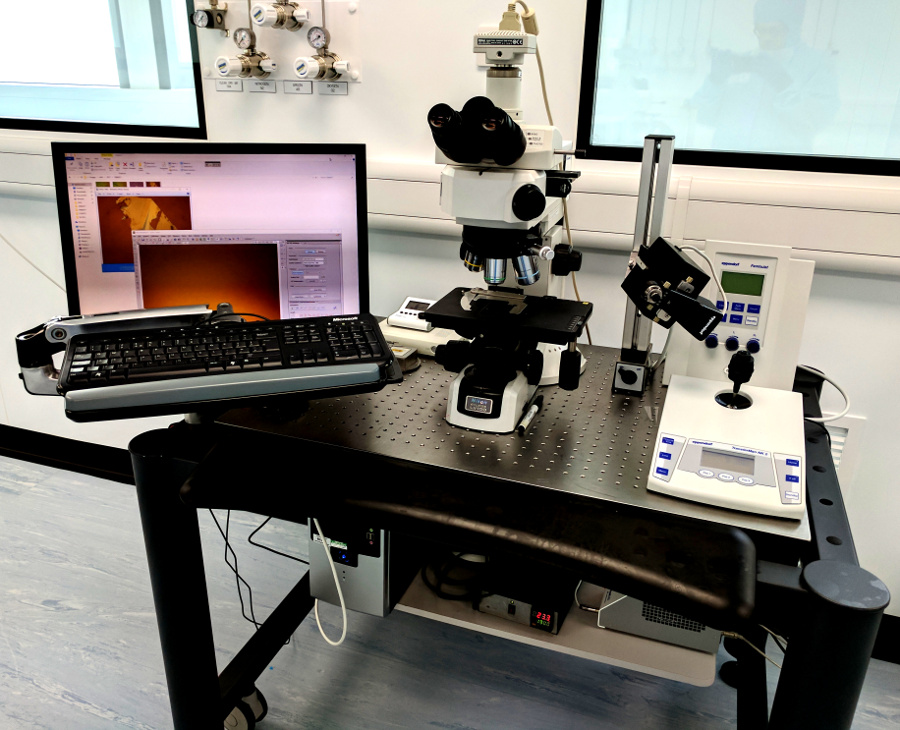

Graphene Transfer Systems x2

The tool is equipped with micro-manipulators and is based on Nikon Eclipse microscope.

Users in charge:

|

|

|

|

|

1k-MTI-furnace

Model: MTI GTF-1200X

Users in charge:

|

|

|

|

|

Acid Bench

This wetbench is used for graphene transfer, cleaning, and a number of other processes involving acids.

|

|

|

|

|

Solvent Bench

This wetbench is used for cleaning, preparation of samples for deposition, etching, as well as any other operations requiring solvents.

|

|

|

|

|

|

|