| enginuity |

|

home | contents | previous | next |

Saving Big Ben

The Jubilee Line Extension to the London Underground, started in 1994, became one of those topics never far from the attentions of the press, especially as the Millennium approached and access to the Dome became an issue. For the civil engineers involved, it was a gigantic project: twin tunnels 11 km long, crossing the river in four places, with eleven new stations to be built, eight of which were to be underground. Professor Robert Mair, Head of the Geotechnical Group, was in the thick of it as Director of GCG, the specialist geotechnical consultants to London Underground for the project.

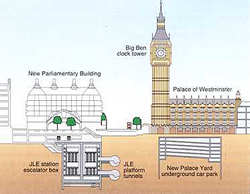

One of the biggest headaches and a very delicate part of the whole construction arose from the decision to put a station right opposite Big Ben. Not only did this require a huge excavation to accommodate seven stories below ground, but the building was also equired to support seven stories above, to provide much needed office space for Members of Parliament. With MPs waiting to move into new offices as well as the Dome about to open, the pressures to produce to deadline were immense.

The technical implications were also immense, with an open hole to be dug to 38m below ground level only 31m away from Big Ben. Built in 1858 following the fire which destroyed the House of Commons, Big Ben is known to be on a shallow foundation. It started to lean towards the North shortly after completion. Any ground movement in the vicinity would exaggerate this lean. The method applied to deal with the settlement of the historic buildings in the area during tunnelling was that of compensation grouting, a process conceived by Professor Mair and his colleagues at GCG and first implemented in the UK on an earlier tunnelling project at Waterloo Station. In this process, a network of horizontal tubes between the tunnels and the ground surface is introduced, each tube having a series of holes. By this means liquid cement can be injected into the ground at any number of points to prevent movement during excavations. Installation of the grouting network itself involves considerable engineering skill.

Instrumentation is attached to Big Ben and to the buildings in the vicinity to measure movement (with some 7000 monitoring points), and computers are used to analyse the data to calculate where and when the grout has to be injected. For Big Ben, a movement of 15 mm at a height of 55m (approximately the height of the clock face above ground level) was taken to be the point at which movement had to be controlled. Grouting episodes typically of 24-hour duration were continued over the whole period during which excavations were occurring - about 28 months. A nail biting time. "Deciding which tube to use for grouting, the volume of grout to be injected and at what rate, is a hugely complex process", explains Professor Mair. "It was calculated that without the grouting, the movement of Big Ben would have gone well over 100mm, which would have caused unacceptable damage. The beauty of the system is that the grouting pipes are still in place, and the site is still being monitored. Compensation grouting can thus, if need be continued until some point as stabilisation is confirmed, althought the instrumentation is showing that no further grounting is now necessary."

For more information, please contact Professor Robert Mair on 01223 332631, e-mail: rjm50@eng.cam.ac.uk

| number 9, July 2000 | home | contents | previous | next |