|

|

||||||||

Mechanics gets sensitive

Tiny mechanical sensors being developed in the Nanoscale Science Laboratory can be used for applications as diverse as testing the performance of turbines, the purity of drinking water and the presence of cholesterol in the blood. These sensors, based on the deflection of a cantilever, have been developed using conventional silicon processing technology, which means they can be incorporated into conventional integrated circuits for a variety of applications. They can be produced to detect minute alterations in either chemical, thermal, stress, mass loading or magnetic signals. Professor Mark Welland explains:

"These structures are about 100mm x 10mm in size, and less than 1mm in thickness. We can sensitise one side of them so that when a gas, chemical or even a particular protein passes over the surface, the structure is caused to bend. It behaves just like a very small mechanical beam. Using a laser of the type found in a CD player, we can detect the movement of the beam, which may be as small as only one atomic displacement, making this type of sensor extremely sensitive."

|

|

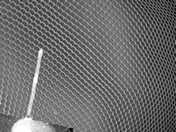

| A sensor, 100mm long, shown in front of a fly's eye, for scale. | |

The small scale of these sensors means that up to around 50 types of sensor can be packed on to a silicon chip only about 1mm2, all measuring and reporting on different things. The chips can then be incorporated into existing electronic technology such as computers or white goods such as fridges and washing machines.