|

|

||||||||

Super Models

The Dawes and Denton codes, as they became known are now used worldwide as an industry standard in the turbomachinery industry. The Dawes code is now being developed for much wider usage. To handle real industrial geometries, considerable attention has also been paid to automating the link between computer aided design (CAD) and CFD via a suite of mesh generating, editing and repair techniques being developed within the CFD Laboratory.

As Dr Mark Savill (CFD Lab manager) explains: "You have to have an understanding of the system you are dealing with to use these kinds of tools, to know whether the answer you have got is sensible or not. That is where the combined expertise of all those involved in the CFD Lab is invaluable. The software that we use is a tool that was developed here, so we know intimately how it works and we have full control of the source code, which is vital when we are pushing the boundaries with our research. Not only that, we have access to experts in the fields of fluid flow, combustion, dispersion and noise who understand the physics of the processes we are dealing with and can therefore provide a sensible analysis of the program outputs. Another key advantage of our general engineering Department is that we can also call on expertise such as heat transfer, petroleum engineering and bio and electrical mechanics and so readily develop interdisciplinary project work."

|

|

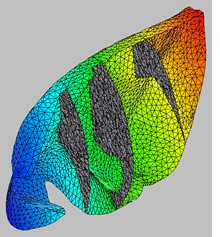

A sectional view through the volume and surface meshes for the left lung of a horse in which air exchange is being studied as part of a collaborative project with Angus Leeming (Imperial College of Science Technology & Medecine). |