| enginuity |

|

home | contents | previous | next |

A Flaming Nuisance

Advanced gas turbine and combined cycle power stations can generate electricity with the highest efficiency, the lowest running cost and most importantly the lowest chemical emissions of any current fossil-fuel system. The world market over the next fifteen years for such industrial gas-turbine power plant is estimated at around £160 billion. However, the new technology that is reducing the chemical emissions is driving power stations to instability.

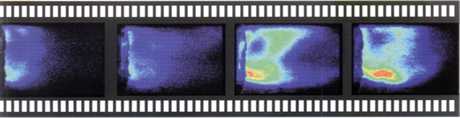

Visualisation of flame shape within a sound cycle.

In recent years, the technique of pre-mixing air and fuel before combustion has allowed reductions in emissions of nitrous and nitric oxides to less than 10% of their previous lowest levels. This type of technology is being applied in the power industry and is planned in the next generation of aeroengines. Unfortunately, pre-mixing of the fuel/air makes the combustion sensitive to sound waves within the combustion chamber. The sound waves make the combustion unsteady, and the unsteady combustion generates yet more sound! Pressure waves can become so intense that structural damage is done. This is a generic problem experienced by all manufacturers of industrial gas turbines and a number of power stations throughout the world have been damaged or are unable to deliver their design output power or emissions.

The combined skills in acoustics, computational fluid dynamics and control within the Department of Engineering are being brought to bear on this problem. The group of researchers are developing theories to explain and predict the occurrence of instability, so that safe and reliable gas turbines can be designed. The theoretical projects are being backed by experiment, and a rig has been installed in a test cell in the Hopkinson Thermodynamics Laboratory, making use of the old chimney, to provide test data to check the theoretical approaches. The group is also developing novel ways of controlling an unstable combustor. It is intended to use techniques similar to those originally developed for anti-sound to feed in the fuel and air mix 'out of phase' to the oscillations set up in the combustion chamber and thus kill the instabilities at source. Techniques of control engineering need to be used to develop suitable feedback strategies.

The research team, lead by Professor Ann Dowling, involves collaboration between four members of the academic staff and a group of nine post-docs, research students and technicians in the Department. Three additional post-docs will start in the New Year. The projects are funded by the EPSRC, the EU, Rolls-Royce plc, National Power, Hitachi and Kawasaki.

For further details please contact Professor Ann Dowling: 01223 332729, e-mail: apd1@eng.cam.ac.uk

| number 8, December '99 | home | contents | previous | next |