| enginuity |

|

home | contents | previous | next |

Hot spots

Next time you heat up your ready meal in the microwave, spare a thought for the complexity of the operation you are about to perform. Dr David Dibben in the Electricity Utilisation Group (EUG), which is part of the Power Group, has been doing just that and has developed a new finite element modelling technique that can be used to calculate the 3-D electric field distribution and therefore predict the temperature that will be produced in an object heated by microwaves.

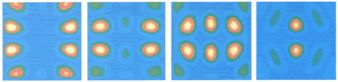

The above diagram shows the large changes in the predicted heating pattern that can be brought about as the frequency changes from 2.44GHz to 2.47GHz.

The method that David has developed is an example of computational electro-magnetics, involving coupled electric and thermal fields, and is used to simulate the conditions of a material processed in a microwave oven. It uses time domain analysis so as to obtain a broadband response. The use of edge elements allows the method to overcome many of the problems associated with traditional electromagnetic finite element schemes. The end result is a software package that can be used on a workstation to calculate the thermal distribution generated in, for instance, a microwave oven. This will provide manufacturers with a design tool that will reduce the number of expensive prototypes that need to be built and should result in a better product, i.e. an oven that produces more uniform heating.

Although the calculation of power density distributions by this finite element method takes many hours of computer time, this is very much shorter than the time needed to build a prototype cavity. The frequency of operation of the magnetron generating the microwaves is critical to the thermal distribution produced in plastic and ceramic samples, with small changes in frequency producing large changes in heating pattern. This is evidenced by comparison between a thermal image and power density calculations from the numerical code (see illustration).

This work typifies the aim of the EUG, headed by Dr Ricky Metaxas, which is to facilitate the transfer of electroheat technology between academe and industry. Other topics of research include modelling of radio frequency heating and hybrid drying techniques. The group attracts support from a consortium of electricity companies.

Enquiries to Dr Ricky Metaxas, on (01223) 332680.

| number 5, summer '96 | home | contents | previous | next |