| enginuity |

|

A gem of an idea

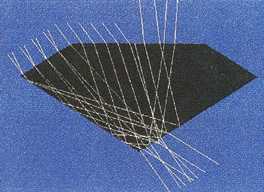

The single-minded enthusiasm of a PhD student, Anandasivam Krishnapillai, has led to the development of an automated process for cutting and faceting gemstones. Working in conjunction with Senior Design Engineer Arthur Timbs, Krishnapillai has developed computer software to artificially replicate the decision-making processes normally carried out by human experts (lapidarists). This allows uncut stones to be analysed, so that the features required, such as brilliance (overall reflective power) and scintillation (how the stone changes its reflectance as it is turned) can be optimised. This is achieved using ray-tracing software to show how light rays will behave in differently cut gemstone shapes. Using a low-powered laser-based system to determine the external geometry and crystal axes, the design can be optimised to minimise wastage. Grinding and polishing can then be carried out with one machine, using diamond and diamond-dust-impregnated copper wheels. A stone can then be cut and polished in approximately 10 minutes to within a few microns.

Ray tracing to determine the optimum design of a gem.

A prototype has been made with a budget of a few hundred pounds, using the traditional university 'string and sealing wax' approach. Although such automation of a craftsman's skill may appear threatening to the traditional gem-cutting industry, there are many other applications for this invention eg lenses for spectacles could be produced within minutes. The process also has potential for producing contact lenses, the aspheric mini-lenses required for virtual reality set-ups, and for 3D television. Not content with their achievements to date, Timbs and Krishnapillai are now working on a prototype which will allow 20 components to be cut at one time.

| number 4, spring '95 |